When to Replace Your Boat Impeller: The Complete Maintenance Guide

- Dec 24, 2025

- 10 min read

Table of Contents

What Your Impeller Does (And Why It Matters)

Your boat's impeller is a small rubber part with flexible vanes that spins inside your water pump. Its only job? Keep your engine from melting down.

Here's how it works: The impeller spins and pulls cool water from outside your boat. That water flows through your engine (or through a heat exchanger if you have a closed cooling system). It carries away heat, then exits through the exhaust. Simple, right?

Without a working impeller, your engine overheats in minutes. Gaskets warp. Seals fail. Metal expands and cracks. In the worst cases, your engine block can crack or your head can warp—repairs that cost thousands of dollars.

Think of your impeller like the water pump in your car. Except your boat's impeller works harder. It runs every single time your engine runs. And unlike your car's water pump, it's made of flexible rubber that breaks down over time.

The worst part? Most boaters never think about their impeller until it fails. And when it fails on the water, you're looking at an expensive tow, a ruined trip, and potentially serious engine damage.

Warning Signs Your Impeller Is Failing

Your boat talks to you. You just need to know what to listen for.

The Early Warning Signs

Weak water flow is your first clue. Some boats have a "telltale" stream—a small stream of water that exits while your engine runs. This stream should be strong and steady. If it's weak, dribbling, or stops completely, your impeller is struggling. Otherwise, you could see more steam than usual coming from the exhaust. Weak water flow also means trouble idling or even getting up to normal speeds.

Strange noises come next. A clicking, squeaking or grinding sound from your water pump area means your impeller vanes are damaged. They're hitting the pump housing as they spin.

Rising temperature is your final warning. Your engine gauge climbs higher than normal. Your overheat alarm beep. By this point, you need to shut down immediately. If you would like in-depth information on boat cooling system failures, check-out this blog Why do Impellers Fail?

What You'll See When You Pull a Failed Impeller

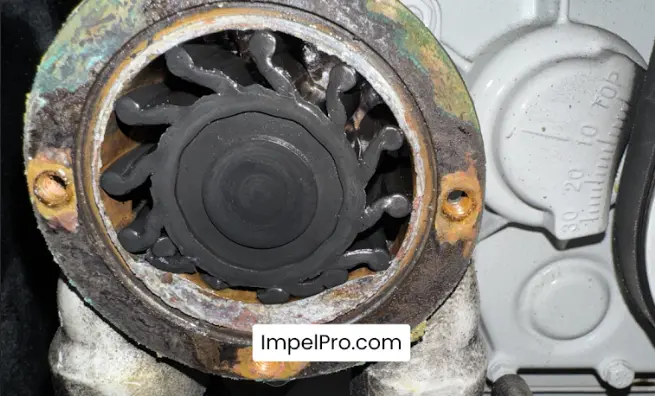

A healthy impeller has straight, flexible vanes. A failing one tells a different story:

Cracked vanes: Small splits that will soon break completely

Set vanes: Vanes bent permanently in one direction (they won't straighten)

Missing pieces: Chunks of rubber floating in your cooling system

Hard, brittle rubber: The impeller feels stiff instead of flexible

Glazed surface: Shiny, melted-looking rubber from overheating

If you see any of these signs, replace the impeller immediately. Don't try to squeeze out "just one more trip." That's how you end up stranded.

When to Replace Your Impeller: The Real Schedule

Ask ten boaters when to replace an impeller, and you'll get ten different answers. Some say every year. Others claim three years is fine. So what's the truth?

The Standard Rule

Replace your impeller every 100 hours or once a year—whichever comes first.

This is what most manufacturers recommend. It's what marine mechanics follow. And it's the safest approach.

Why once a year even if you barely use your boat? Because rubber breaks down whether you run your engine or not. It is worse if you are not running your boat. It dries out. It cracks. It loses flexibility.

The "Every Three Years" Myth

You'll hear experienced boaters say they replace impellers every three years with no problems. And some get away with it—if they're lucky and their conditions are perfect.

But here's what they're not telling you: They're gambling. They might check their impeller twice a season. They might run in clean, cool water. They might have a backup plan if something fails.

The cost of a new impeller? Around $40-120. The cost of an engine overheating? Potentially thousands. The math is simple.

When to Replace More Often

Some conditions destroy impellers faster. Replace every instance if you:

Boat in sandy or muddy water: Sediment acts like sandpaper on rubber vanes

Navigate in brackish water: Salt accelerates rubber breakdown

Run in weedy areas: Plants can wrap around vanes and tear them

Store your boat dry through winter: Long periods without water can crack rubber

Special Cases

You bought a used boat? Replace the impeller immediately. You don't know its age or condition. Consider it part of your purchase cost.

You're planning a long cruise? Install a fresh impeller before you leave. Carry a spare. It's cheap insurance.

What Kills Impellers (And How to Prevent It)

Understanding what destroys impellers helps you avoid problems before they start.

Dry Running: The Instant Killer

Running your engine without water—even for 30 seconds—can wreck an impeller. The rubber heats up, melts slightly, and sticks to the pump housing. The vanes tear when you try to run it again.

How it happens:

Flushing your engine with the flush port closed

Running on a trailer without a flush attachment

Sucking air because your intake is clogged with weeds

Low water levels that expose your intake

Prevention: Always verify water flow before you start your engine. If you're on a trailer, use a proper flush attachment. Never assume water is flowing.

Debris Damage: The Slow Killer

Sand, mud, and plant material work like sandpaper inside your pump. Each particle grinds away tiny bits of rubber. Over time, vanes get thin, crack, and break.

You can't always avoid debris. But you can minimize damage:

Check your intake screen regularly

Rinse your cooling system with fresh water after running in sandy areas

Avoid running in shallow water where you stir up bottom sediment

Replace your impeller more often if you boat in dirty water

Age and Storage: The Silent Killer

Rubber deteriorates whether you use it or not. Sunlight, ozone, heat, and time all break down the molecular structure. An impeller that sits for two years might look fine but crack the first time you run it.

If your boat sits for extended periods (months at a time): The best approach is to replace your impeller at the start of each boating season, before your first trip. Think of it as cheap insurance—you're starting fresh with a known-good part.

Many boaters ask about removing and storing their impeller during winter. While this can work with some removal methods, if you use the ImpelPro puller, the impeller goes straight to the trash. The tool's sharp teeth grip the rubber to get it out—but they damage the impeller in the process. You can't reuse it.

This isn't a downside. Here's why: An impeller that sat through winter in your pump is already compromised. The vanes have been flexed in one position for months. The rubber has dried out. For the cost of a $30-60 replacement, you get peace of mind knowing your cooling system will work when you need it.

Smart boaters follow this schedule:

Spring: Install a fresh impeller before launching

During season: Inspect at mid-season if you boat heavily

Fall: Leave the old impeller in place through winter (no need to remove it)

Next spring: Pull and discard the old impeller, install a new one

The impeller becomes an annual "consumable" like oil filters or spark plugs. Budget for it. Plan for it. And you'll never worry about cooling system failure.

Chemical Damage

Using the wrong lubricants can destroy an impeller fast. Always use water-based or glycerin-based lubricant. Never use petroleum products like oil or grease—they cause rubber to swell and break down.

Make Impeller Changes Easy

Changing an impeller shouldn't require two hands, three tools, and a yoga certification. The ImpelPro impeller puller makes the job simple—even in tight spaces where you can barely fit your hand.

Designed by a marine mechanic who got tired of fighting stubborn impellers, it works where other tools fail.

Learn More About the ImpelPro Difference

Tools You Need for Easy Impeller Changes

Having the right tools turns a frustrating job into a 15-minute task. Here's what you need:

Essential Tools

Tape measure - measure the diameter of the impeller from vane to vane

ImpelPro Impeller Puller – Removes stuck impellers in tight spaces (Standard or Large size depending on your impeller)

9/16" Socket or wrench – Works with the ImpelPro puller to engage the bearing system

Spare impeller kit – Keep one on board always

Water-based lubricant – For installing the new impeller

Socket set – For removing pump cover screws

Shop towels – Things get wet

Why You Need a Proper Puller

Many boaters try to remove impellers with pliers, screwdrivers, or picks. This usually fails or damages the back seal or water pump. Impellers grip the pump shaft tight. Vanes bend and tear when you pull at the wrong angle.

The ImpelPro puller solves these problems:

Sharp teeth bite into rubber for a secure grip

Bearing system distributes pulling force evenly as you wind out the impeller

Works one-handed in spaces where you can barely reach

Fits all common impeller sizes from generators and sailboats to large yachts

Always follow your engine manufacturer's instructions when servicing your cooling system. This guide provides general information—your specific engine may have unique requirements.

How to Replace Your Impeller in Minutes

Changing an impeller isn't complicated. Here's the basic process:

Step-by-Step Overview

1. Turn off water from seacock/through-valve: Turn off engine and make sure nobody can start it. Open your engine compartment and locate the water shutoff, turn it off to stop the flow of water.

2. Locate the water pump and remove the pump cover: Take out the screws holding the faceplate. Keep track of them—they like to roll into dark corners. Also, it is good practice to know which way the pump cover goes back on. Line up the same way as you removed to avoid any leaks.

3. Pull the old impeller: This is where most people struggle. Insert ImpelPro puller into the pump avoiding the cam. Tighten the thumbscrew so the arms grip onto the impeller hub. Tighten the rod using a 9/16" socket. The bearing system winds the impeller straight off the shaft.

4. Inspect the pump housing: Look inside for rubber chunks from the old impeller. Run your hand inside the pump to check for scratches or corrosion. Clean everything thoroughly.

5. Lubricate the new impeller: Coat the vanes with water-based lubricant. This helps them slide into the housing without tearing.

6. Install the new impeller: Fold the vanes over and push the impeller onto the shaft. The vanes will snap into place inside the housing, especially when you turn over the engine. No need to line them in a certain direction.

7. Replace the cover: Use a new gasket if needed. Tighten screws in a cross pattern to ensure even sealing.

8. Don’t forget to turn back on the water from the seacock/through valve.

9. Test it: Start your engine and check for strong water flow, check your temps, touch the cover plate of the pump to make sure it is cool. Watch It Done

Seeing is believing. Watch this 60-90 second video showing Eddie Protzeller, the inventor of ImpelPro, change an impeller start to finish. You'll see how easy it is—even in a tight space.

Watch: How to Change an Impeller with ImpelPro → Large Impeller In Action

For detailed step-by-step instructions with photos, check out our complete ImpelPro user guide.

Be Ready—Not Stranded

Here's a scenario that plays out every weekend: A boat breaks down miles from the marina. The engine overheated. The impeller failed. The boater doesn't have a spare or the tools to change it.

Now they're waiting hours for a tow. Their day is ruined. And they're paying hundreds of dollars for something they could have fixed in 15 minutes.

Why Boaters Skip Impeller Maintenance

We hear the same reasons over and over:

"I can't reach my water pump." Engine compartments are cramped. Water pumps hide in corners. Getting your hand in there is hard. Using two hands? Nearly impossible.

"I'll just have my mechanic do it." That's fine—until you're 20 miles offshore. Or it's Sunday and the shop is closed. Or you're on a lake with no marine services nearby.

"I tried once and couldn't get the impeller out." This is incredibly common. Impellers stick to the shaft. Regular pliers slip off. You end up tearing the rubber and giving up.

"It seems fine, so why bother?" Because impellers don't give you much warning. They work fine, then suddenly they don't. And by then, your engine is already overheating.

The Cost of Being Unprepared

What an impeller costs: $40-120 What the ImpelPro puller costs: $185-215 What a tow costs: $300-800 What engine damage costs: $2,000-10,000+

Do the math. Being prepared costs less than a tank of gas.

Your Impeller Maintenance Kit

Keep these items on board every trip:

Spare impeller (in a sealed bag to prevent drying)

ImpelPro impeller puller

9/16" socket or wrench

Water-based lubricant

Basic screwdrivers

Shop towels

Your water pump manual

Store everything together in a waterproof bag. Label it clearly. Tell your crew where it is.

Don't Get Caught Without the Right Tool

The ImpelPro impeller puller was designed by a marine mechanic who needed a tool that actually works in real boat engine compartments. Sharp teeth grip tight. The bearing system pulls straight. And it works one-handed in spaces where other tools fail.

Choose your size:

Standard Puller – For most Inboard and Sterndrive Impellers, Generators And Large ballast pump impellers .

Large Puller – For larger boats, Sports Fishing, and Yachts.

Buy the ImpelPro Standard Puller

Buy the ImpelPro Large Puller

FREE: Printable Boat Maintenance Checklist

Never forget critical maintenance again. Download our complete seasonal checklist—including impeller inspection schedules, tool lists, and maintenance logs.

Your Peace of Mind Starts Here

Your boat is your escape. Your freedom. Your investment. Protecting it doesn't require complicated procedures or expensive service appointments. It just requires attention to the small things that matter.

An impeller is one of those small things. It costs less than dinner out. It takes 15 minutes to change. And it's the difference between a great day on the water and an expensive disaster.

Check your impeller regularly. Replace it on schedule—or more often if conditions demand it.

Keep a spare on board. And invest in a tool that makes the job simple instead of frustrating.

With regular impeller maintenance, you'll avoid costly repairs, prevent breakdowns, and spend more time enjoying the water instead of worrying about it.

About the Author

Eddie Protzeller is a tugboat and yacht mechanic with over 15 years of experience maintaining and repairing inboard engines. After years of fighting stuck impellers in impossible-to-reach water pumps, he invented the ImpelPro impeller puller—a tool that finally works the way mechanics need it to. Eddie has tested the ImpelPro on hundreds of engines in real-world conditions, from small fishing boats to large cruisers. His goal is simple: make boat maintenance easier so boaters spend less time in the engine compartment and more time on the water.

Safety Note: Always follow your engine manufacturer's service procedures and safety guidelines. Shut off your engine before working on cooling system components. Wear eye protection when removing pump covers, as stored pressure can spray water. If you're unsure about any procedure, consult a qualified marine mechanic or please reach out to us at customercare@impelpro.com See the full lineup of ImpelPro impeller pullers at impelpro.com